Virgin Coconut Oil is derived from the fresh meat or kernel of a mature fruit of coconut rather than the sundried coconut meat known as copra. Virgin Coconut Oils are produced one of two ways: Quick drying of fresh coconut meat, which is then used to extract the oil by mechanical means, wet-milling method. Coconut milk first is extracted from fresh coconut meat by mechanical pressing. The oil is then extracted from coconut milk by way of boiling, fermentation, refrigeration, enzymes or mechanical centrifuge.

Virgin Coconut Oil is water clear in colour, has mild sweet aroma. VCO is chemical and additive free, and is the purest form of coconut oil. Virgin Coconut Oil is currently hot topic due to its benefits to human consumption and the researchers challenge on the dogma, which is the domination of diet-heart hypothesis in atherosclerosis research.

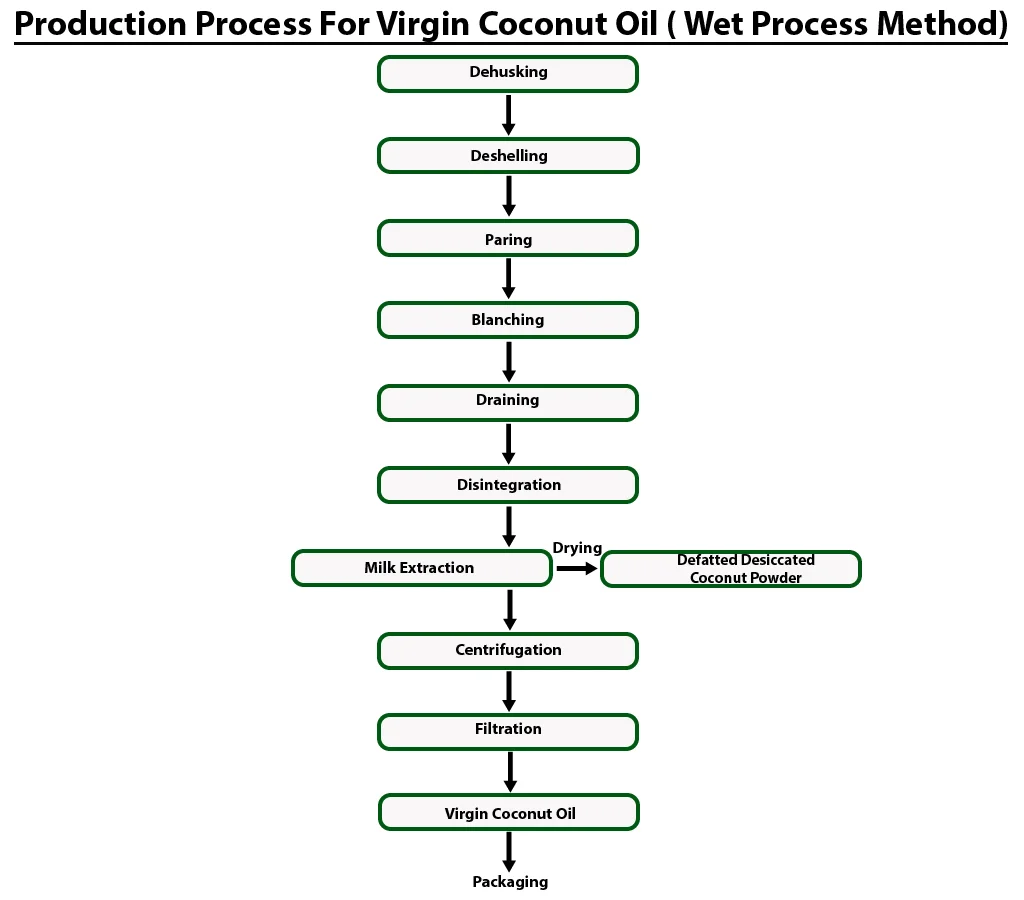

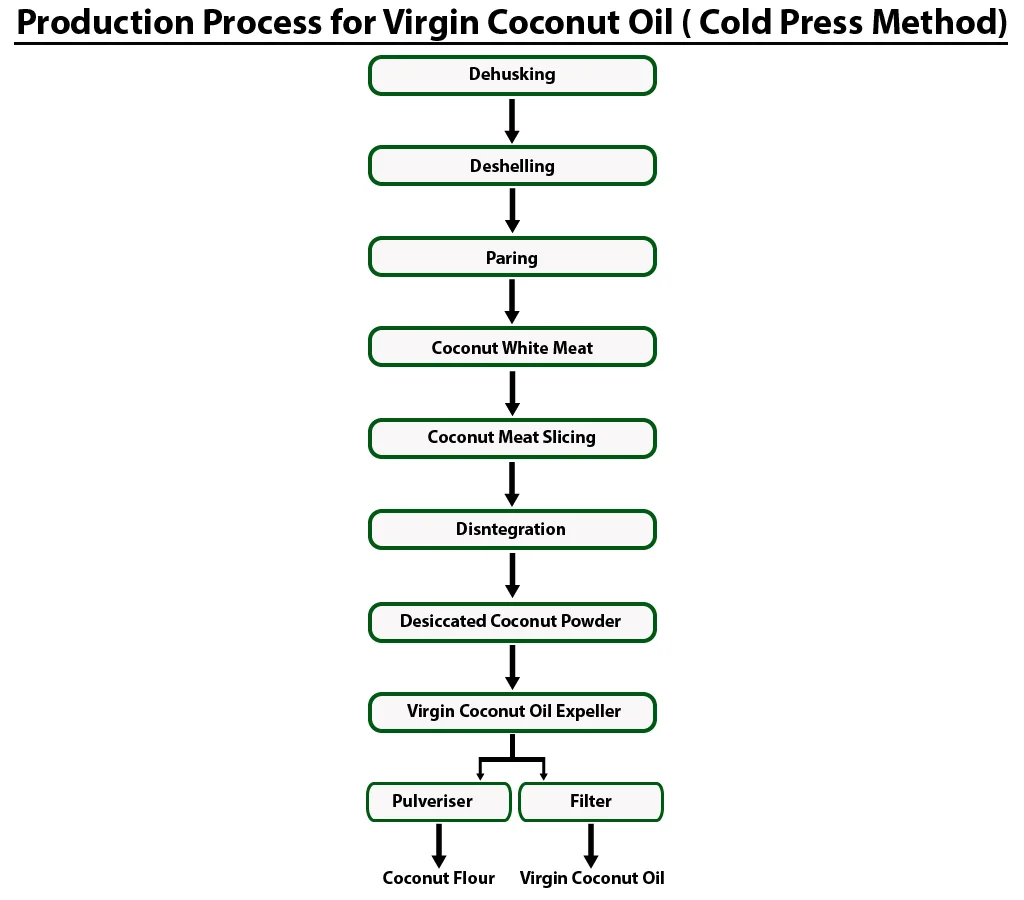

Dehusking:

Husk is removed manually or with the help of coconut dehusking machine.

Deshelling:

It is done to remove the shell of the coconut. This is done without breaking the kernel.

Paring:

It is done to remove the brown skin of the kernel with the help of a paring machine.

Blanching:

Pared coconuts are dipped in boiling water for few minutes in a blanching tank.

Draining:

It can be done with the help of vibratory screener. This will remove the excess water present in the blanched coconuts.

Disintegration:

Pared coconuts are fed into a disintegrator where pared nuts are cut into small pieces and will be ready for extraction.

Milk extraction:

Shredded coconuts are put into a milk extractor (screw press/ hydraulic press) and coconut milk oozes out of the extractor. Extracted milk is collected in collecting vessels. Extracted coconut milk is then filtered to remove if any solids are present. Residue obtained after extraction is dried in an oven and packed a defatted desiccated coconut.

Centrifugation:

This process is used to separate two immiscible substances. Coconut milk is the natural oil in water emulsion. After centrifugation, oil and skim milk is separated. Coconut oil is separated from coconut milk.

Filtration:

The oil is passed through the filter and packed in consumer packs. Vacuum dehydration of oils will remove the excess moisture present in oils.

Essential Composition and Quality factors of VCO as per APCC

| S.No | Parameters | |

|---|---|---|

| 1 | Moistures(%) | Max 0.1 |

| 2 | Matters Volatile at 1200C(%) | Max 0.2 |

| 3 | Free Fatty Acid(%) | Max 0.2 |

| 4 | Peroxide Value meq/kg | Max 3 |

| 5 | Relative density | 0.915 - 0.920 |

| 6 | Refractive index at 400C | 1.4480 - 1.4492 |

| 7 | Insoluble impurities per cent by mass | Max 0.05 |

| 8 | Saponification Value | 250 - 260 min |

| 9 | Iodine Value | 4.1 - 11 |

| 10 | Unsaponifiable matter % by mass | Max 0.2 - 0.5 |

| 11 | Specific gravity at 30 deg./30 deg. C | 0.915 - 0.920 |

| 12 | Polenske Value | min 13 |

| 13 | Total Plate Count | < 0.5 |

| 14 | Color | Water Clean |

| 15 | Odor and Taste | Natural fresh coconut scent, free of sediment, free from rancid odor and taste |

Gas Liquid Chromatography (GLC) Ranges of Fatty Acid Components

| S.No | Common Name | Composition | % |

|---|---|---|---|

| 1 | Caproic acid | C6:0 | 0.10 - 0.95 |

| 2 | Caprylic acid | C8:0 | 4 - 10 |

| 3 | Capric acid | C10:0 | 4 - 8 |

| 4 | Lauric acid | C12:0 | 45 - 56 |

| 5 | Myristic acid | C14:0 | 16 - 21 |

| 6 | Palmitic acid | C16:0 | 7.5 - 10.2 |

| 7 | Stearic acid | C18:0 | 2 - 4 |

| 8 | Oleic acid | C18:1 | 4.5 - 10 |

| 9 | Linoleic acid | C18:2 | 0.7 - 2.5 |

Critical points to consider in Virgin Coconut Oil processing Coconut Selection:

Maturity of coconut is a very important factor in the quality and recovery of Virgin Coconut Oil especially in processes involving the coconut milk route. Coconut kernels from fully mature coconut have the highest oil content and are relatively low protein content.

Coconut milk is an emulsion of oil and water stabilized by protein. To release the oil from coconut milk, the protein bond has to be broken so more oil can be recovered if the kernel from which the coconut milk is obtained has high oil content and lower protein content. As an indicator of maturity of nut, husk and shell is brown in colour and gives sloshing sound when shaken.

Always ensure that the nut while fully mature do not have haustorium. This is because the oil content of the kernel and quality of the oil starts declining once the haustorium is formed.

Sanitation and Handling of Equipments:

Coconut meat/kernel and coconut milk are low acid foods so they are very susceptible to microbial contamination. Because of this, strict sanitation in the plant area,personnel and equipment should be practiced at all the times. Food grade stainless steel is the recommended material of construction for all parts of Virgin Coconut Oil process equipments that will come in contact with coconut kernel or milk. Water to be used as diluent or rehydrating agent should be of high quality, free from microbial contamination and from too much mineral content.

Handling of Virgin Coconut Oil product:

Presence of water in oil will make the product’s shelf life short i.e. water in oil will cause rancidity upon storage. Ensure that the water content of the virgin coconut oil is less than 0.1% and that any process container or packaging material to be used for VCO are thoroughly dried and clean.

By products in Virgin Coconut Oil units:

Major by-products in Virgin Coconut Oil units are shell, parings (brown skin) and defatted Desiccated coconut powder.

Share your requirements with us